The Task

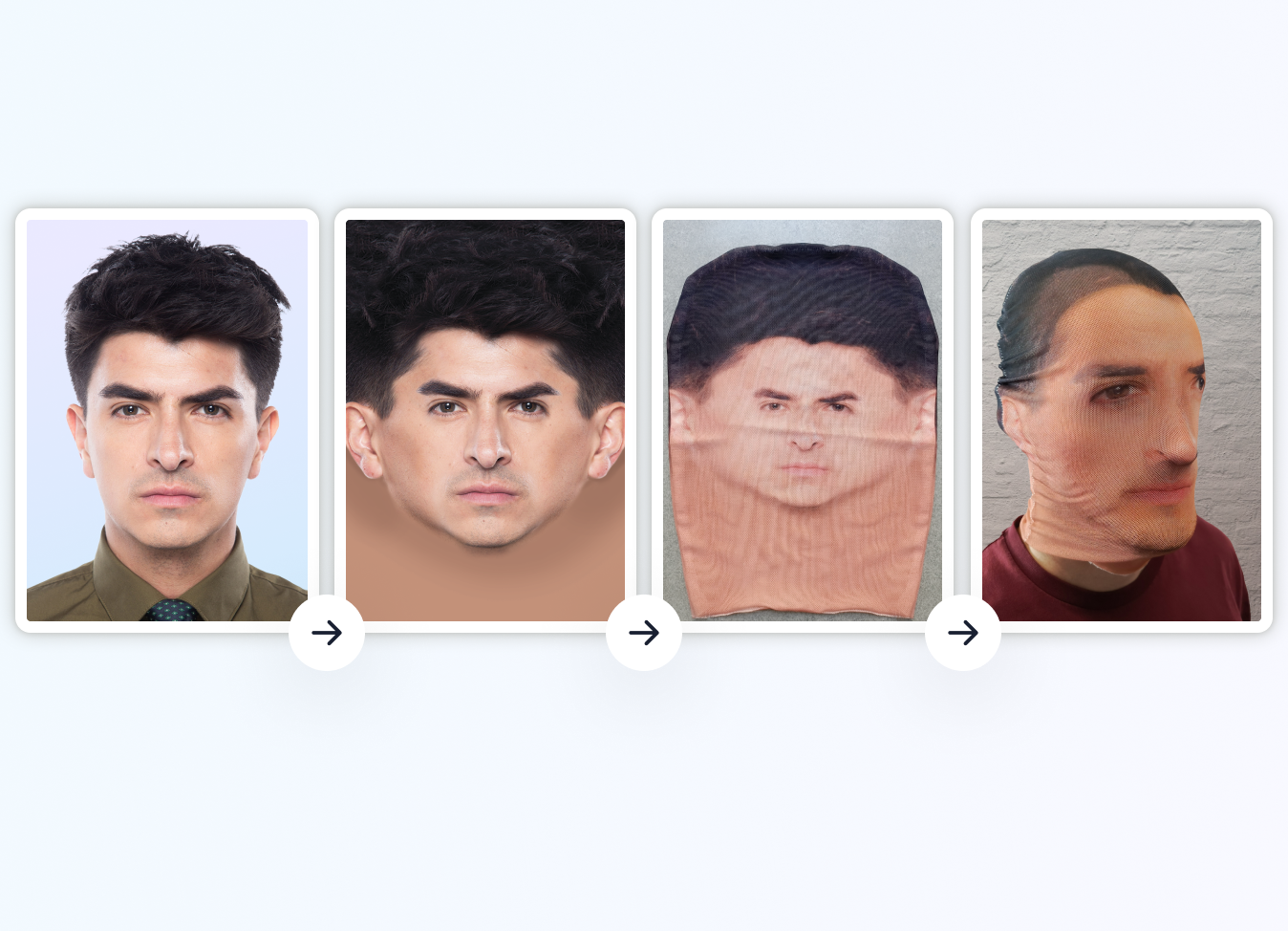

The goal was to create fabric masks that accurately mimic human facial features for biometric testing. Standard masks typically cover only the front of the face (180°), but our dataset required full coverage, including the back and sides, so respondents could move naturally without compromising data integrity.

Key requirements included:

- Full head contour for multi-angle recognition

- High-quality, realistic prints with modular replaceable features (eyes, nose, mouth)

- Material flexibility, including thinner fabrics similar to nylon hosiery for enhanced biometric testing accuracy

The Solution

-

- 01

-

3D Design and Production

We developed a 3D breakdown of the head structure to guide the supplier. This allowed:

- Integration of fabric with complete head coverage

- Customizable inserts for facial features to increase realism

- Post-production assembly that preserves the head’s natural shape

-

- 02

-

Material Selection and Printing

Different fabrics were tested, including lightweight, semi-transparent options, which better simulate skin and allow anti-spoofing testing. Prints were optimized for:

- Hyper-realistic textures and pigmentation, including micro-details like freckles or subtle wrinkles

- Multi-layered construction for durable, realistic results

-

- 03

-

Process Optimization

Even with a capable supplier, fabric mask production involves scaling challenges. We:

- Standardized instructions for assembly and quality control

- Monitored consistency across samples and materials

- Ensured flexibility to swap parts for live testing scenarios

The Result

Successfully produced initial samples for early-stage testing with full head coverage

Created a scalable workflow for future production of hyper-realistic fabric masks

Established expertise in multi-angle, realistic mask fabrication for biometric validation