The Task

A retail client approached us with a clear goal:

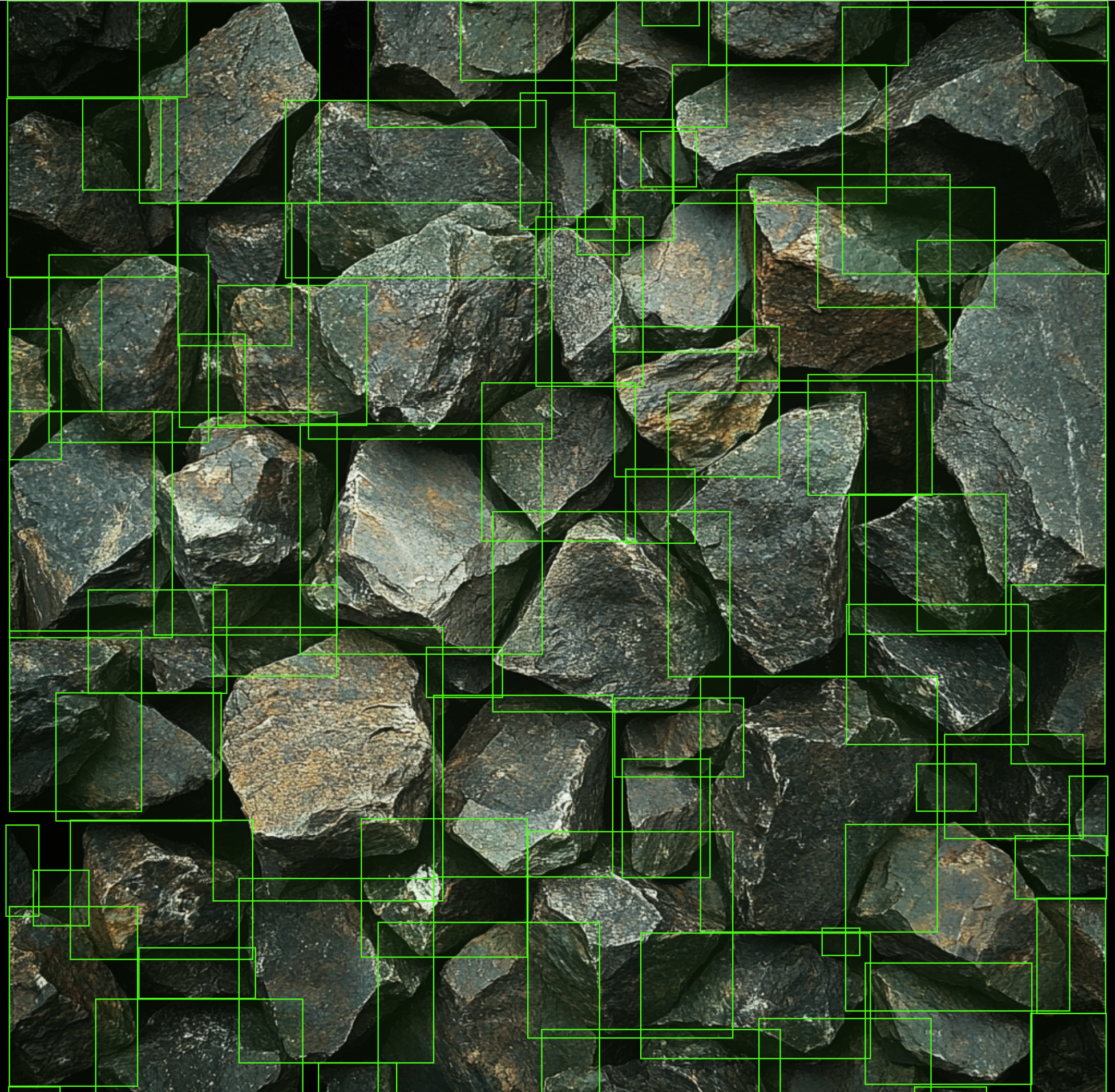

Automate the process of monitoring grocery store shelves using neural networks.

They needed a dataset that would enable a machine learning model to detect and classify products on shelves in real time. The end use case?

– Measure the success of promotions

– Optimize shelf space

– Respond faster to stockouts

But there was a significant challenge:

Shelves were filled with a huge variety of products—different brands, categories, package designs, and frequent seasonal updates. Traditional annotation workflows weren’t going to cut it.

The Solution

-

- 01

-

Structuring the Work

We split our team into two focused groups:

- Product Research Team:

This team created a taxonomy of product categories. They studied the client’s inventory, researched visual differences between product types, and developed detailed classification criteria for annotators. - Annotation Team:

Using these guidelines, annotators worked on labeling every image with high precision, tagging product types, positions on the shelf, and packaging variations.

-

- 02

-

Tooling and Workflow Setup

- We used a combination of internal QA dashboards and custom labeling tools to track accuracy.

- A feedback loop was built in—researchers could refine guidelines based on edge cases found by annotators.

- Weekly calibration sessions ensured that annotators and researchers were always aligned.

-

- 03

-

Quality Assurance

- A dual-pass review process was implemented: all images were reviewed by a second annotator.

- Random samples were escalated to experts for manual audit.

- Discrepancies were analyzed to refine both training and guidelines.

The Result

40% Cost Reduction:

By streamlining roles and using task specialization, we lowered total project costs significantly.High-Precision Dataset:

The annotated images provided clean, structured training data for the client’s neural network, supporting accurate real-time shelf analytics.Better Business Insights:

The client could now evaluate promotional campaign results in real time, detect planogram violations, and improve in-store execution.