The Task

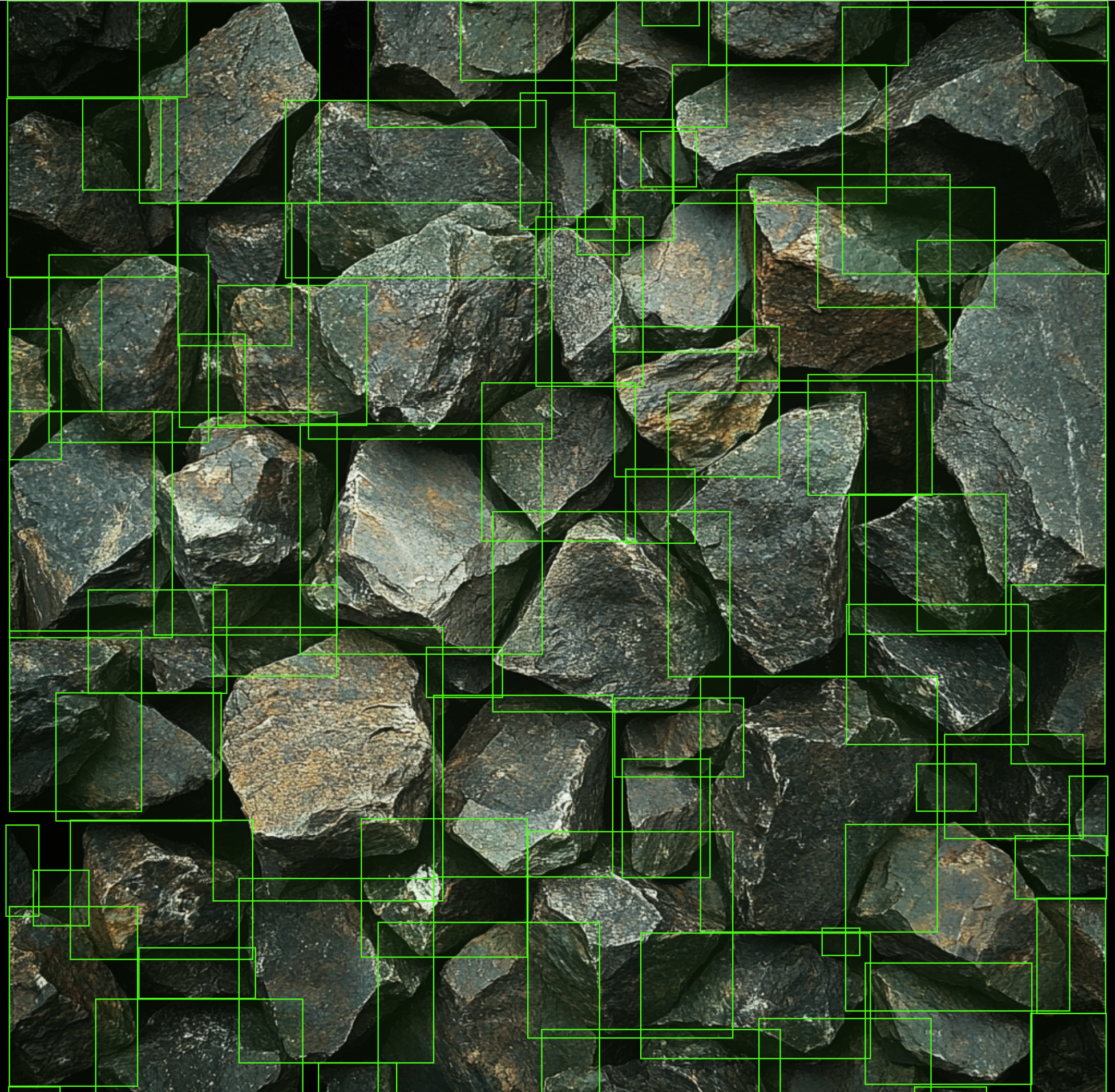

A mining company needed annotated data to train a neural network that would automatically assess ore fragment sizes and detect oversized pieces in real time on a conveyor belt.

They had tried working with other vendors—but ran into trouble:

Validation was inconsistent. Internal QA took too long. They had to involve their own annotation team, which wasn’t sustainable.

They needed a reliable partner who could take over the entire cycle: annotation, quality control, and fast delivery—all within a week and a half.

To complicate things further, the ore images were collected in the field during a business trip. Delays weren’t an option.

The Solution

-

- 01

-

Fast Team Assembly & Workflow Optimization

- We formed a team of 13 annotators within 24 hours.

- From the start, we noticed a slowdown in the annotation software—each image contained a large number of polygons, and the system lagged.

Our workaround:

Split each image into four parts, annotate them separately, and then stitch everything back together for final review.

This allowed us to maintain speed without sacrificing precision.

-

- 02

-

Multi-Level Validation Process

- Each annotated batch went through several layers of QA.

- We streamlined communication between validators and annotators to reduce feedback loops.

- Our internal experts handled all edge cases—no client input was needed.

The Result

Fast Turnaround:

We completed the full cycle of annotation and validation in just 1.5 weeks.Reduced Overhead for the Client:

The client no longer had to manage annotation or QA internally.High-Quality Data:

The pilot confirmed data quality met production-grade standards, with no additional review needed from the client.